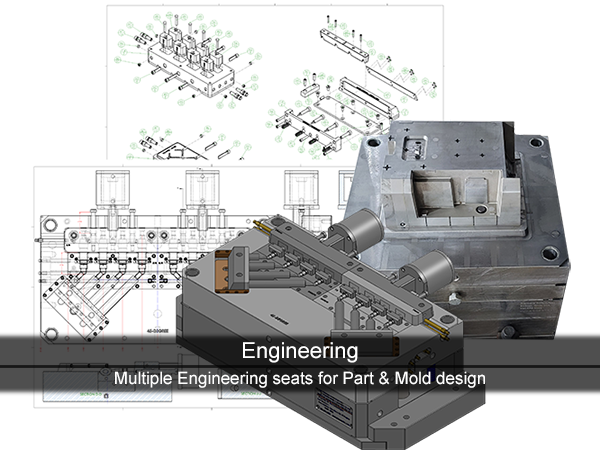

Since any project begins with development, we encourage you to utilize Premere’s extensive thermoplastic experience to navigate the interdependence between Part and Mold.

Having the latest in 3d modeling software we will assist you in any of the design steps along the way; from concept, to part, to mold.

Design

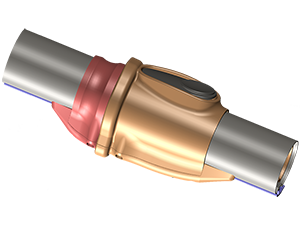

Premere has a full functioning thermoplastic injection mold building, maintenance, and repair facility.

With multiple CNC machines, fed by CAM software, we are quite capable of producing or repairing molds ranging from small single cavity to large multi-cavity in size.

Tooling

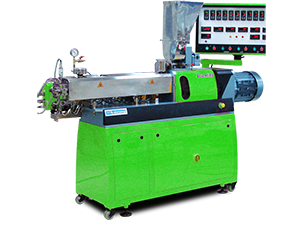

Premere has a wide range of horizontal thermoplastic injection molding presses, ranging from a 50-ton clamp capacity up to 1000-tons. Included with those we also have a vertical shuttle press for specialized molding.

We injection mold nearly all materials from Engineering grades to commodity resins.

Molding

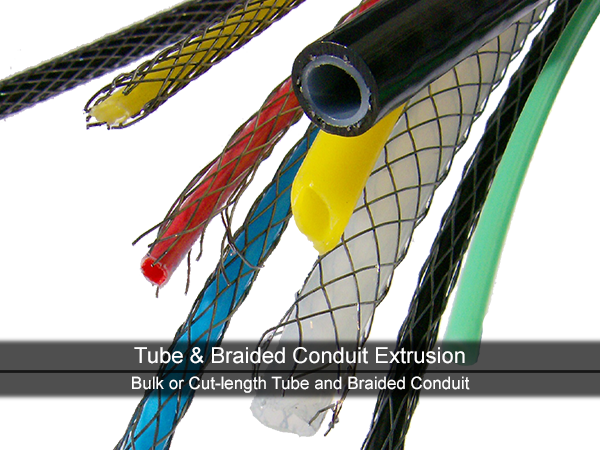

Serving multiple industries from Automotive to Furniture, we supply both small diameter Tube to Braided Conduit in both cut-to-length and in bulk spools.

On the outer diameter we can also provide paint marking for identification and or “notching” to add grip strength for attached or molded parts.

Extrusion