Tube & Braided Conduit

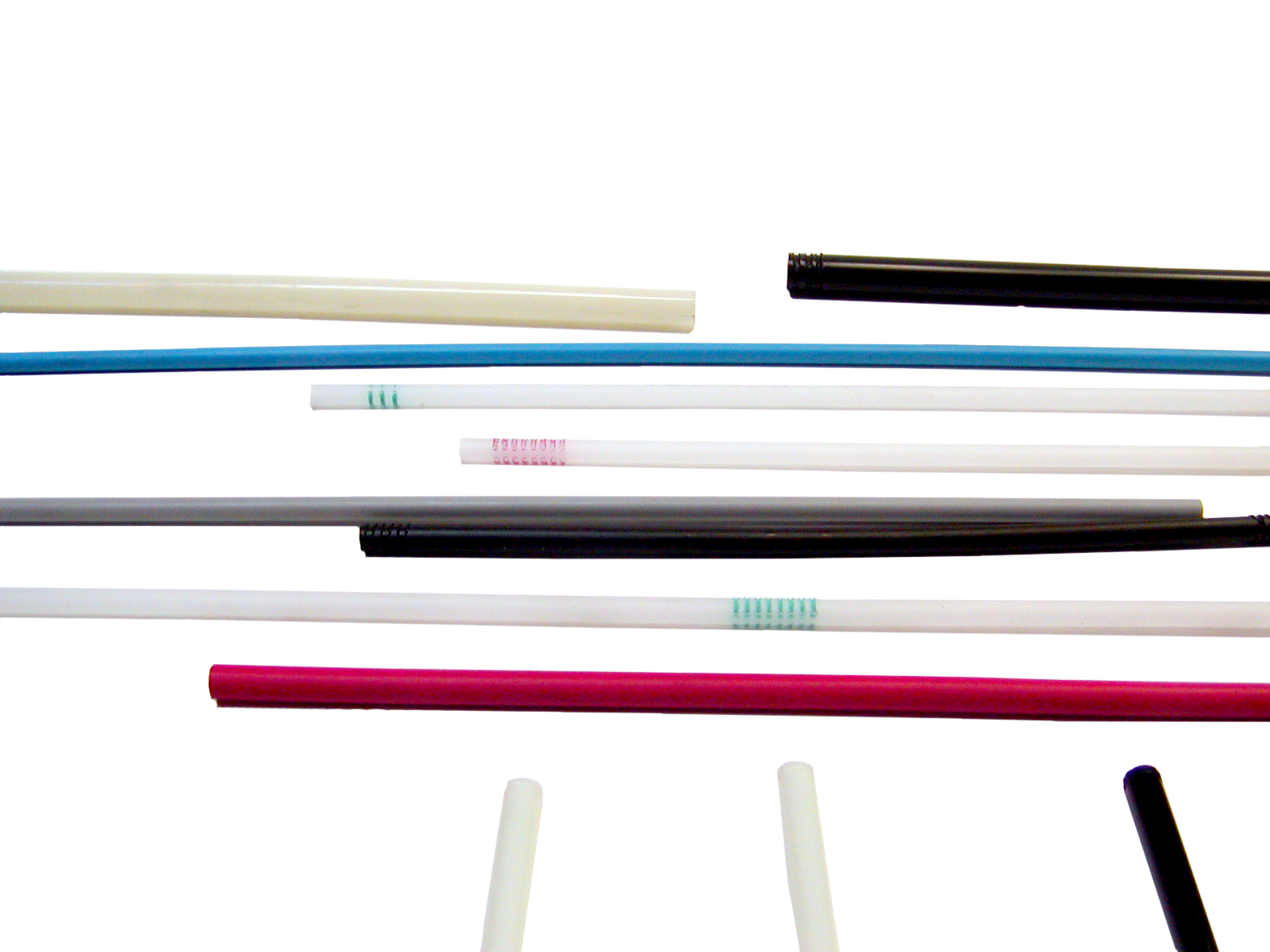

Premere manufactures custom liners and tubing for multiple uses. The “tube”, is singular in its construction, in that it is a cylindrical part with a specified ID and OD. Some of the uses of this type of construction would be for:

To enhance the structure of the Tube, we add a secondary jacket to increase wall thickness, toughness, durability, structural support or many other purposes. Should you need even more strength, we can add various types of wire over top of the internal liner in the form of either a Braid, Long-lay, Lay-wire, Bowden, or even a flat wrap.

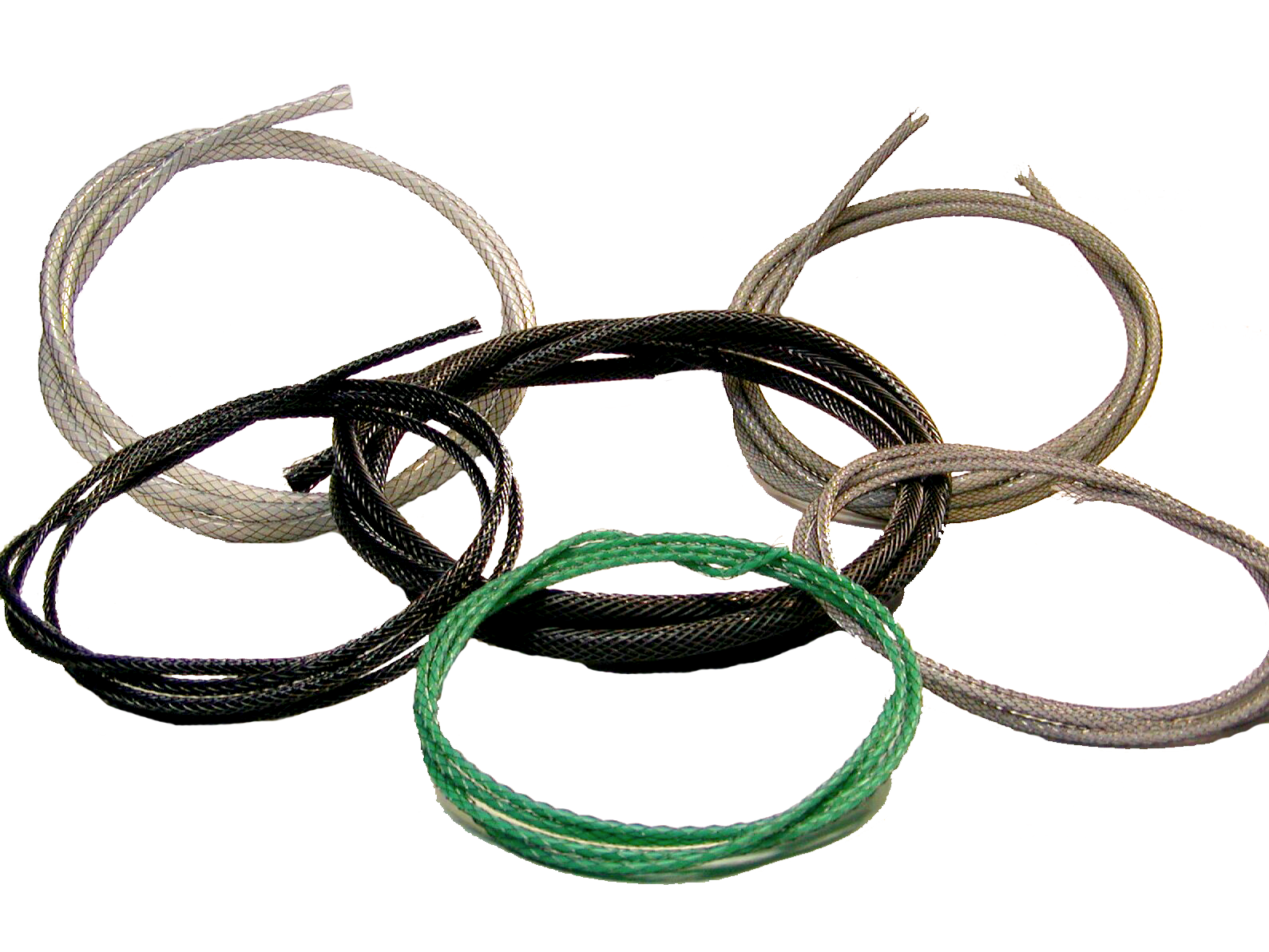

Braided Conduit is made by a series of processes starting with a basic tube, commonly referred to as a liner. The liner is put into the braiding process where wire is wrapped or laid to provided compression and structural strength as well as abrasion resistance. Then this combination is coated with a plastic polymer to encapsulate both the liner and the wire to complete the process.

Braided conduit is used in variety of applications such as:

As added enhancements we can add various colored markings or ID’s to either the Tube or Conduit for better identification. We also can add a “notch” or “serration” to the outside diameters to add for “grip” strength to any attached part.